Welcome to this website!

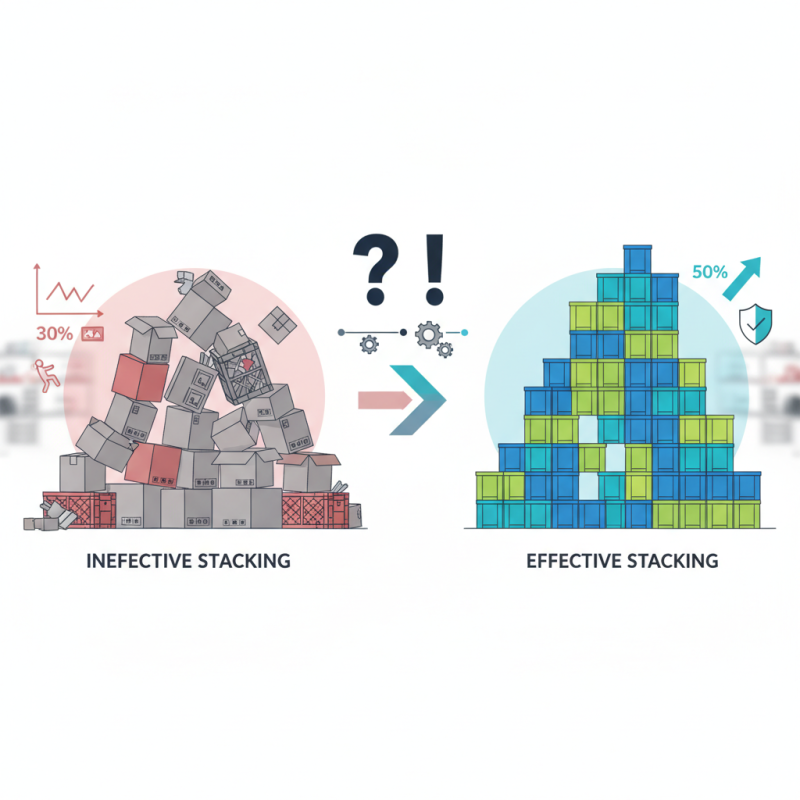

In today's logistics and warehousing sectors, the efficient use of space is paramount for optimizing operations and reducing costs. According to industry reports, approximately 30% of warehouse space remains underutilized due to ineffective stacking practices. This inefficiency not only leads to increased operational costs but also poses risks to safety and inventory management. Proper stacking containers can significantly enhance space utilization, improving storage capacity by as much as 50% when executed with best practices in mind.

Moreover, the strategic stacking of containers is critical for ensuring safety in warehousing environments. The Occupational Safety and Health Administration (OSHA) states that improper stacking techniques can lead to workplace accidents, accounting for almost 25% of all warehouse-related injuries. By adopting effective stacking strategies, companies can mitigate these risks while maximizing their storage potential. As the need for efficient supply chain operations continues to grow, understanding and implementing best practices for stacking containers is increasingly vital for businesses aiming for operational excellence and safety compliance.

When it comes to maximizing space efficiency in container stacking, understanding the core principles is essential. Effective stacking begins with a thorough assessment of container weights and stability. Each container's load capacity should be meticulously calculated to avoid exceeding the maximum weight limits that can lead to collapses. It is vital to evenly distribute weight across the stack, placing heavier containers at the bottom. This careful arrangement not only preserves structural integrity but also enhances safety during handling and transport.

Another important aspect of container stacking is ensuring proper alignment. Containers should be stacked in a way that minimizes gaps and overlaps, which can lead to potential hazards. Using stacking frames or nets can help secure the containers and maintain their position, providing added safety. Additionally, establishing clear stacking patterns, such as one-over-one or interlaced arrangements, can contribute to more stable configurations. By adhering to these principles, companies can effectively utilize vertical storage space, streamline operations, and ensure a safe working environment for all personnel involved in the handling process.

| Container Type | Max Weight (kg) | Max Stacking Height (m) | Base Dimensions (m) | Material | Recommended Usage |

|---|---|---|---|---|---|

| 20ft Standard Container | 2240 | 6.0 | 6.058 x 2.438 | Steel | General Cargo |

| 40ft High Cube Container | 2670 | 9.5 | 12.192 x 2.438 | Steel | Large Goods and Storage |

| 10ft Container | 1400 | 5.0 | 3.058 x 2.438 | Steel | Small Goods and Tools |

| Reefer Container | 3000 | 6.0 | 6.058 x 2.438 | Steel and Insulation | Perishable Goods |

| Flat Rack Container | 20000 | 1.5 | 12.192 x 2.438 | Steel | Heavy Equipment |

When it comes to stacking containers, the choice of the right containers is paramount for both safety and space efficiency. According to industry reports, up to 30% of warehouse space can be wasted due to poor container selection and inadequate stacking methods. Selecting containers made from sturdy materials, such as high-density polyethylene or reinforced metal, ensures they can withstand the weight of stacked items without compromising structural integrity. The correct container design should consider height, width, and load capacity, aligning with the specific items being stored to optimize vertical space utilization.

Moreover, understanding load distribution is critical. A recent study by logistics experts highlighted that improper stacking can lead to a staggering 25% increase in workplace accidents, emphasizing the importance of selecting containers with secure stacking features. Containers with built-in interlocking designs or anti-slip surfaces can significantly reduce the risk of toppled stacks, thereby enhancing safety in the work environment. By carefully choosing containers that facilitate safer stacking and maximize space, organizations not only improve operational efficiency but also contribute to a more secure workplace environment, leading to reduced injury rates and improved productivity.

When stacking containers, safety and space efficiency must be prioritized to maximize storage capacities across various environments. In warehouses, for instance, utilizing uniform container sizes can facilitate stable stacking. Always place heavier containers on the bottom and lighter ones on top to lower the center of gravity and prevent topple risks. Furthermore, ensure each stack is secured, either by using container ties or stacking frames, to withstand sudden movements, especially in seismic-prone areas.

In outdoor settings, such as construction sites, careful consideration of the ground conditions is essential. Stacks should be placed on level surfaces to prevent leaning or collapsing. Utilizing tarps or covers can protect the containers from environmental factors, thus maintaining their integrity. Additionally, clear labeling on the stacks will promote safety by ensuring that workers can quickly identify contents without having to disturb the arrangement, reducing the likelihood of accidents during retrieval operations.

When it comes to stacking containers, safety must be the top priority to avoid accidents that can lead to injuries or costly damages. According to the Occupational Safety and Health Administration (OSHA), improper stacking is among the leading causes of workplace incidents in warehouses and logistics centers, accounting for approximately 25% of all reported accidents. It is essential to establish clear guidelines on how containers should be stacked, considering factors such as container weight distribution, stability, and the surface on which they are placed.

Moreover, the American Society of Safety Professionals (ASSP) emphasizes the importance of regular training for workers involved in container handling. Ensuring that workers are educated on proper stacking techniques, including the use of appropriate equipment for lifting and securing loads, significantly reduces the risk of accidents. Stack heights should be regulated, with recommendations to keep stacks below five feet for stability, unless additional industrial safety measures are implemented. Regular inspections and safety audits can identify potential hazards, helping organizations maintain a safe working environment while maximizing space efficiency.

By adhering to these safety considerations, companies can protect their workforce and reduce liability risks significantly. A report by the National Safety Council (NSC) indicates that firms investing in safety training and equipment see a 40% reduction in workplace injuries over an extended period, highlighting the financial as well as safety benefits of prioritizing proper container stacking practices.

Monitoring and maintaining stacked containers is crucial for achieving optimal performance in any logistics operation. A well-organized stacking strategy not only maximizes space efficiency but also ensures that safety standards are consistently met. According to a report by the International Maritime Organization, improper stacking can lead to potential accidents, which is why continuous monitoring of weight distribution and structural integrity is essential. Implementing regular inspections can help identify any issues early, ensuring that containers are securely stacked and that weight limits are adhered to.

Additionally, leveraging technology can enhance the maintenance of stacked containers. IoT devices can be deployed to monitor conditions such as temperature and humidity, which are vital for the safe storage of certain materials. A study from the Supply Chain Management Review found that companies that utilize real-time monitoring systems improve their operational efficiency by up to 30%. This proactive approach not only reduces the likelihood of damage but also optimizes stack performance by ensuring that containers are managed based on their specific requirements.

Tips: Regularly schedule visual and structural inspections to preemptively address any emerging issues. Utilize software solutions that integrate with existing management systems for better tracking of container conditions. Encourage a culture of safety and awareness among staff to maintain high standards in container handling and stacking.